…Allow me to explain.

At the end of last summer, my wife and I decided to finish our basement. We’d planned on doing so since we bought our house three years ago, and we thought this past Winter would be a good time to tackle the project.

The space formerly known as the gym

Shortly after that decision was made, I was recruited for a position at a new employer. It was a good opportunity, and I accepted an offer in the Fall. The only down side was that this new employer was located an hour and a half’s drive from our house.

Since it was Fall, we decided to carry on with the basement project, as doing so would increase the value of the house in time for the local real estate market to heat up in the Spring. We’d deal with the long commute, and move as soon as we could sell the house.

For the first few months, I continued to train, but cut back on volume and treated the remodeling project as accessory work. After all, hanging drywall isn’t exactly a cake walk. By time January rolled around, I realized the schedule was getting tighter and cut back even further on lifting in order to get further on the basement.

…And then it happened. I was wrapping up an evening of successful drywall work. With one last piece to hang, I had two cuts and few screws between me and dinner. Sure enough, I slipped on the second cut and caught my thumb to the tune of four stitches.

Stitches

Lifting stopped. Drywall stopped. I couldn’t grip anything for three weeks.

By time the cut had healed, the schedule was blown, and the priority list no longer included lifting. From February through April, it’s been a mad dash to get the basement finished, get the house listed and sold, and find a new house closer to the new job.

We finished the basement in March, but since that’s where the gym was, I couldn’t exactly jump back into lifting. Further, it’s been until last week that we’ve been wrapping up the details for selling and buying the homes. Now that life has calmed back down, the urge to reclaim my physical capacity has inspired me!

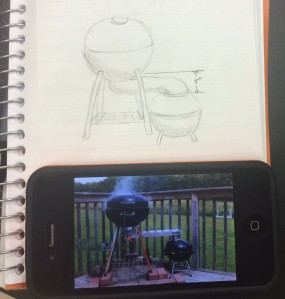

I cleared out a space in my garage. It’s only about 50 square feet, but its room enough for the old squat stands, a barbell and a few plates.

The simple bare necessities!

Since we haven’t moved yet, time is still limited. And, with the four month hiatus, I’m not exactly in peak condition. The plan, then, is simply to start where I am: lift a few times per week, hit the major lifts, and slowly progress. For the next few weeks, I won’t be on any particular program. I’ll just be trying to do a little more each time in order to re-acclimate to lifting.

It’s a long road… but it’s worth the effort! Here’s to new beginnings!